Bandsaw Restoration: T-Nut for Fixed Vice Jaw

|

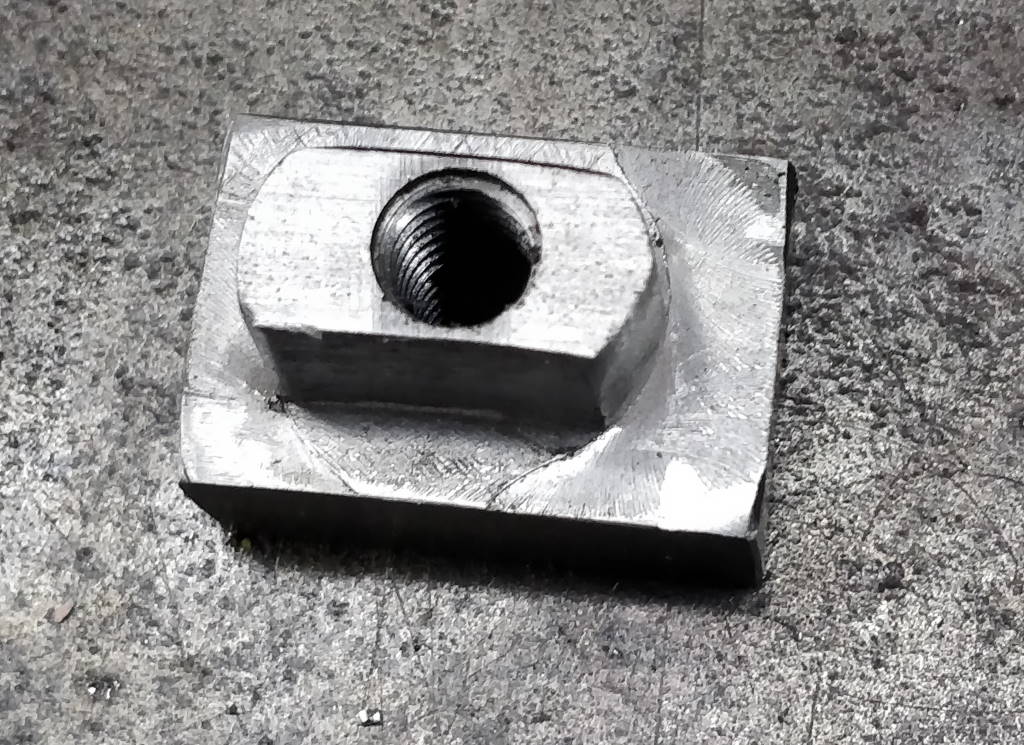

The new base for the bandsaw has a top shelf to stop swarf from falling down onto the shelves. This makes it impossible to access the underside of the bandsaw bottom casting and hence there's no way to get a spanner onto the nut used for the fixed vice jaw. To allow the vice to be adjusted, this t-nut has been custom made. Due to the 105 mm radius of the slot in which the vice rotates, this t-nut has been machined with the same radius.

|

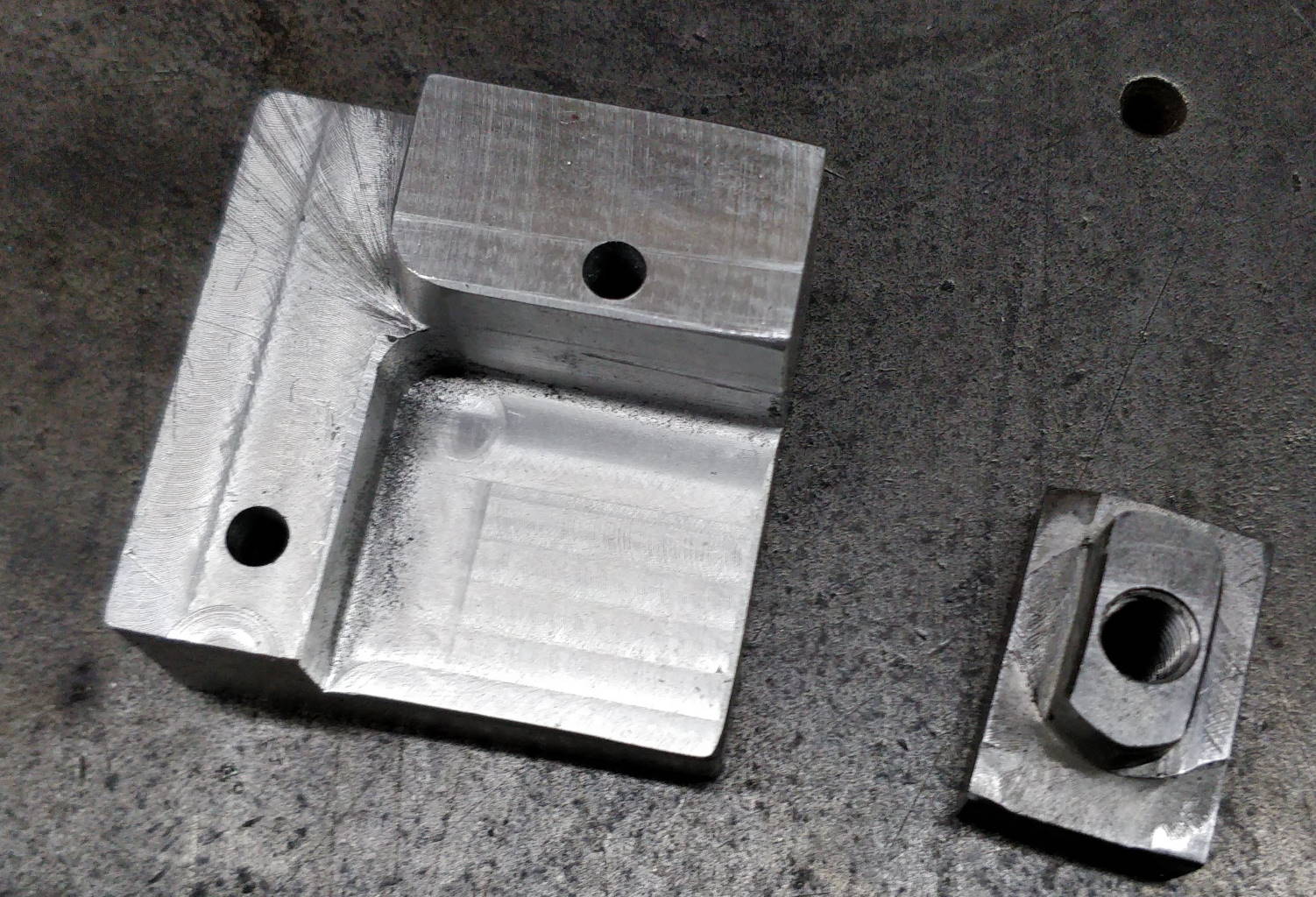

This photo shows how the nut will sit in the underside of the bottom bandsaw casting. It also shows how the bottom casting was mounted in the mill vice to allow some improvements to be made to that casting. The moving jaw of the milling vice is sitting in the slot in the casting in which the moving jaw nut slides; the fixed jaw of the milling vice is against the rear side of the casting. The rear side of the casting is not perpendicular to the machined face on the top of the casting and hence the grip from the milling vice is very weak. To compensate for this, I only took very light cuts when working on the casting in this configuration.

|  |

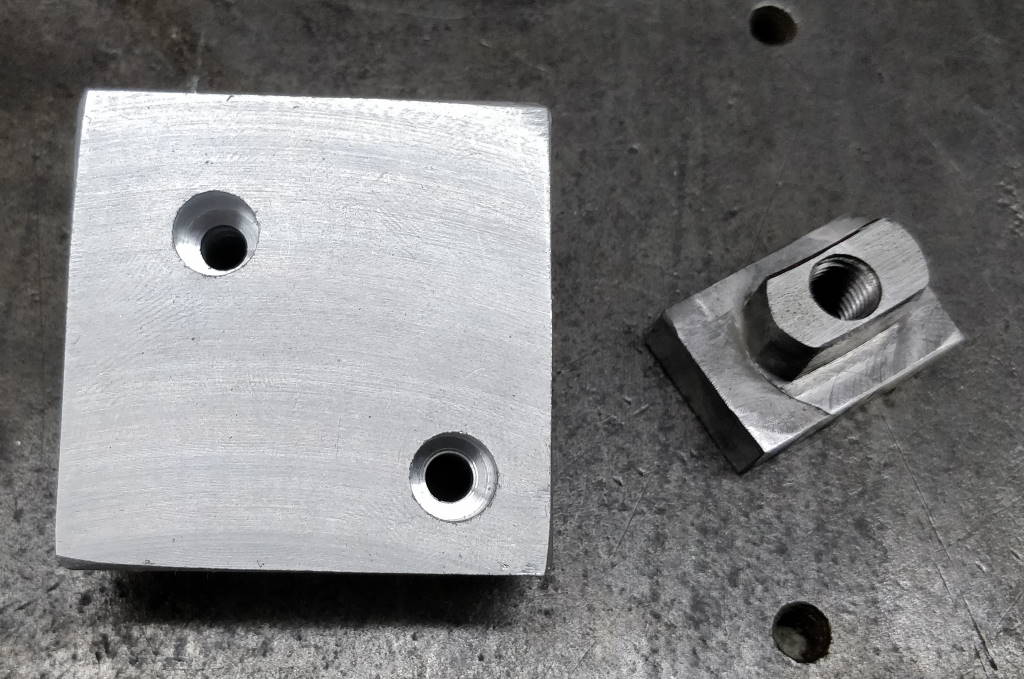

Since the new base will prevent access from underneath, I was concerned that, should I ever wish to remove the fixed vice jaw from the bandsaw, the t-nut would drop onto the top shelf of the base and I would not be able to re-fit the jaw. To prevent this from being an issue, I decided to make a "t-nut saver" to catch the t-nut if it falls. To mount this "t-nut saver", I drilled and tapped (M5) two blind holes in the casting, as shown in this photo. I used the DRO to position them relative to one another so that I could use the same positions when making the "t-nut saver".

|

This photo shows a better view of the casting mounted on the milling machine. The ends are not supported, but all the work I was doing on the casting was in the central area.

|  |

While the casting was mounted in the milling vice, I decided to skim the surface on which the t-nut will slide. This should improve the action of the t-nut compared to pulling against a cast face. Due to the weak hold on the casting in the vice, I took very light cuts with the end mill.

|  |

These photos show the "t-nut saver". It was machined out of a short length of 50 mm square aluminium bar (cut off from the original bar with a slitting saw as my bandsaw is in pieces!). The two counterbored holes are for the M5 mounting screws (positioned to match the holes drilled and tapped in the casting); the different levels correspond with the depths of the areas in the casting. The radius on the corner of the thickest section was made using a belt sander; all the other features were made on the milling machine.

|

This photo shows the "t-nut saver" next to its home on the underside of the base casting.

|

This photo shows it fitted. As you can see, it only provides protection to the t-nut when the fixed vice jaw is in its 90° cutting position. If the screw is removed while the jaw is mounted at an angle, retrieving the t-nut could be challenging (although it's possible it could be done with a magnet). As I don't expect to remove the fixed vice jaw very often, I decided it would be safe as I can simply ensure that the vice is in the correct place before undoing the screw.

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.