Threading Banjos

|  |

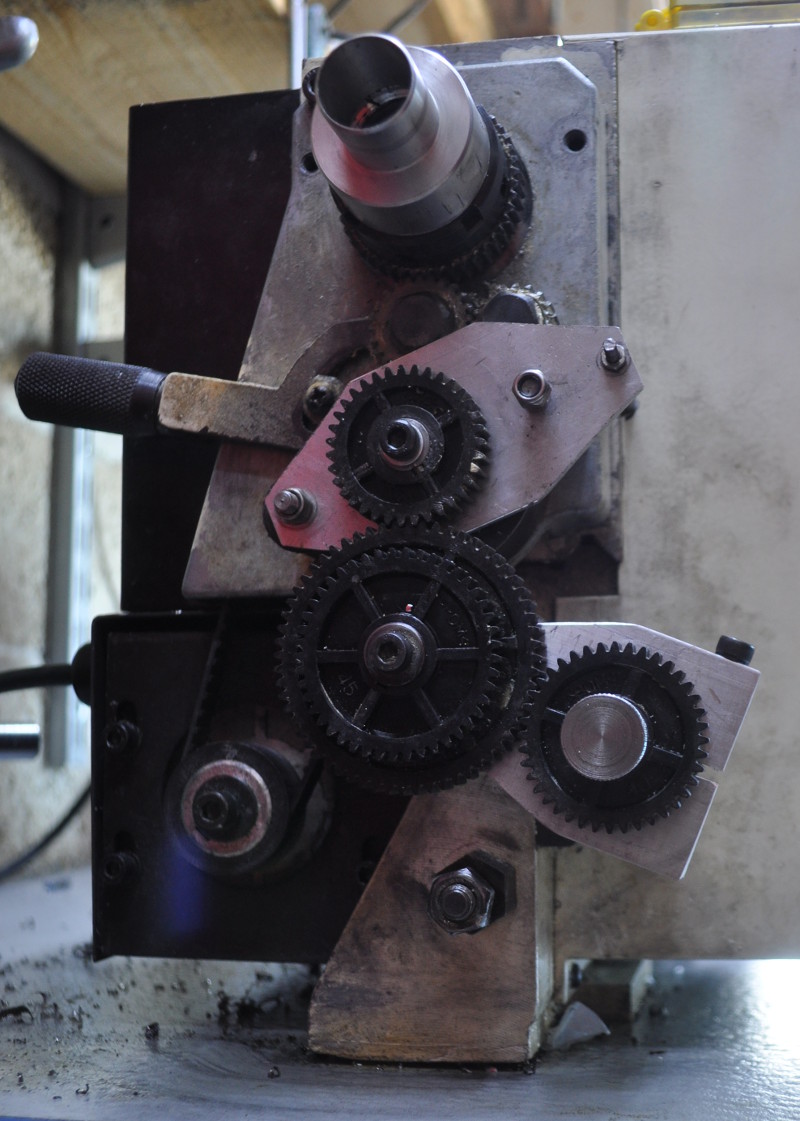

The banjo that comes with the mini-lathe is difficult to use: it is hard to adjust and the nuts are awkward to access. Richard Hagenbuch designed a new banjo that was simple to make and much simpler to use than the standard one. My version of Richard's banjo is shown on the left of the image above. Apart from being converted to metric, this is identical to Richard's design.

Richard Hagenbuch's Banjo

|  |

The simplicity of the Richard's design compared to the standard mini-lathe banjo can be seen in these photos. On the left is the standard banjo. On the right are the parts I made to make the banjo to Richard's design. The M6 cup-head screw is a close sliding fit in the slot in the banjo. The two shaped nuts at the top of the image are turned from two M6 coupling nuts. A section of each nut is turned down to 8 mm diameter such that the combined length of the 8 mm sections is 16.5 mm. This allow the gears to run freely. The banjo itself is made from 8 mm aluminium with a significant portion of it thinned down to allow for the thickness of the nut part of the lower coupling nut.

Having made Richard's banjo, I found that it was very easy to use, but required two alignment steps in order to set it up. The first step involves mounting the banjo on the lead-screw pillow-block extension, fitting the gears on the movable shaft and the gear on the lead-screw and then adjusting the position of moving shaft to get a good mesh. This is relatively awkward due to space constraints at the left and rear of the lathe (although far easier than the standard banjo). The second step is relatively simple: it just involves rotating the whole banjo to get a good mesh with the primary gear.

A Much Simpler Banjo

For the vast majority of the pitches that I screw-cut, the middle gear is an idler. This means that it is entirely up to me what gear I choose. It occurred to me that I may be able to standardise on the location of the movable shaft and cut most pitches without adjustment. Using my change gear calculator, I did some investigation and quickly concluded that almost every pitch I ever cut could be achieved with a 50 mm gear spacing. The change gears on the mini-lathe are module 1, which makes the gear spacing in millimetres very easy to calculate: it is the arithmetic mean of the number of teeth on the two gears: (X+Y)/2. For pitches where the middle gear is just an idler, this means that the number of teeth in gear B and gear D (using the mini-lathe's notation) must add up to 100 to maintain a 50 mm spacing.

| Pitch | Gear A | Gear B | Gear D |

|---|---|---|---|

| 0.50 | 20 | 40 | 60 |

| 0.75 | 30 | 40 | 60 |

| 1.00 | 40 | 40 | 60 |

| 1.25 | 50 | 40 | 60 |

| 1.50 | 40 | 60 | 40 |

| 2.00 | 60 | 55 | 45 |

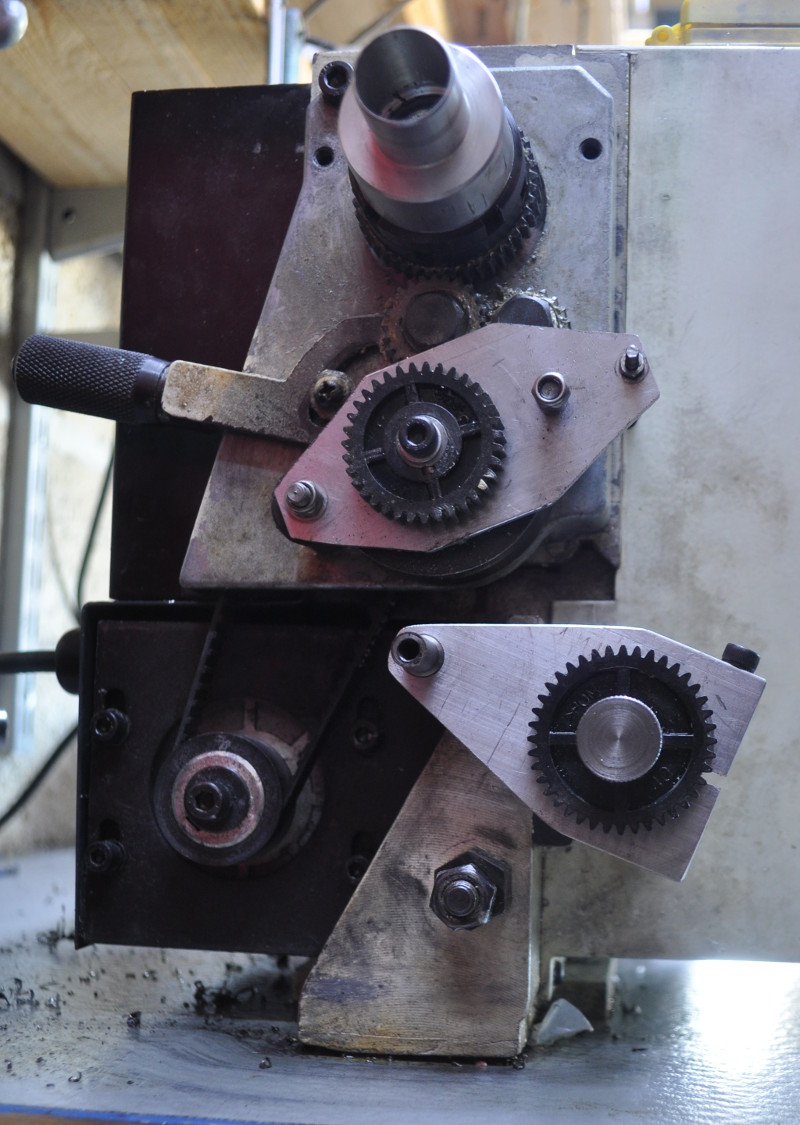

Based on these results, I made a new and very simple threading banjo that you can see on the right of the header photo. This is made out of 50 mm × 8 mm aluminium. The only critical dimension is that between the centre of the 20 mm hole for the pillow-block and the centre of the 8 mm shaft for the intermediate gear. This spacing was set at 50.1 mm to allow a good running fit between the gears.

|  |

The body was slit with a 3 mm slitting saw and an M5 clamping screw holds it onto the pillow-block. The hole for the shaft is tapped M6 and counterbored 10 mm to a depth of 3 mm. To shape the body, I cut it roughly on the bandsaw and cleaned it up with a file.

The shaft is made out of 10 mm silver steel. The middle section is left at 10 mm for 4 mm length such that 1 mm protrudes out of the counterbore and keeps the gear from rubbing against the aluminium body. It has a 5 mm section threaded M6 to hold it onto the body and a 16.5 mm length of 8 mm diameter for the gear carrier to run on. An M5 tapped hole is used to hold the gear carrier on the shaft.

For simplicity, I left the shaft 16.5 mm long to take the standard two-gear carrier. After making the banjo, it occurred to me that it might be possible to use the banjo for threads that require a two-step change as long as gear C and gear D have a 50 mm spacing:

| Pitch | Gear A | Gear B | Gear C | Gear D |

|---|---|---|---|---|

| 0.40 | 20 | 50 | 40 | 60 |

| 0.45 | 60 | 50 | 20 | 80 |

| 0.70 | 35 | 50 | 40 | 60 |

| 0.80 | 40 | 50 | 40 | 60 |

| 1.75 | 35 | 45 | 60 | 40 |

| 2.50 | 50 | 45 | 60 | 40 |

With the addition of an extra 50 tooth gear (available from arceurotrade for £3.32 at the time of writing), it is also possible to cut 0.6 mm pitch gears. The complete gear chart is shown below.

| Pitch | Gear A | Gear B | Gear C | Gear D |

|---|---|---|---|---|

| 0.40 | 20 | 50 | 40 | 60 |

| 0.45 | 60 | 50 | 20 | 80 |

| 0.50 | 20 | 40 | 60 | |

| 0.60 | 20 | 50 | 50 | |

| 0.70 | 35 | 50 | 40 | 60 |

| 0.75 | 30 | 40 | 60 | |

| 0.80 | 40 | 50 | 40 | 60 |

| 1.00 | 40 | 40 | 60 | |

| 1.25 | 50 | 40 | 60 | |

| 1.50 | 40 | 60 | 40 | |

| 1.75 | 35 | 45 | 60 | 40 |

| 2.00 | 60 | 55 | 45 | |

| 2.50 | 50 | 45 | 60 | 40 |

So the new banjo allows me to cut every standard metric thread between 0.4 mm and 2.5 mm pitch. It is extremely easy to set up as the only adjustment is the angle of the banjo to gain a good mesh with gear A. This can be adjusted with a 4 mm hex (Allen) key with easy access from the front of the lathe.

The spacing for 0.5 mm pitch threads is a little short (the lead-screw shaft and transfer-gear shaft are about 82 mm apart and the total gear spacing for this ratio is only 80 mm), but I usually use a die when cutting threads with such a fine pitch and if necessary, it works better than one would imagine. I could also consider substituting the 0.5 mm gears with a four-gear system: 40/80/40/60, which would have less of an issue with spacing but be more awkward to set up.

|  |

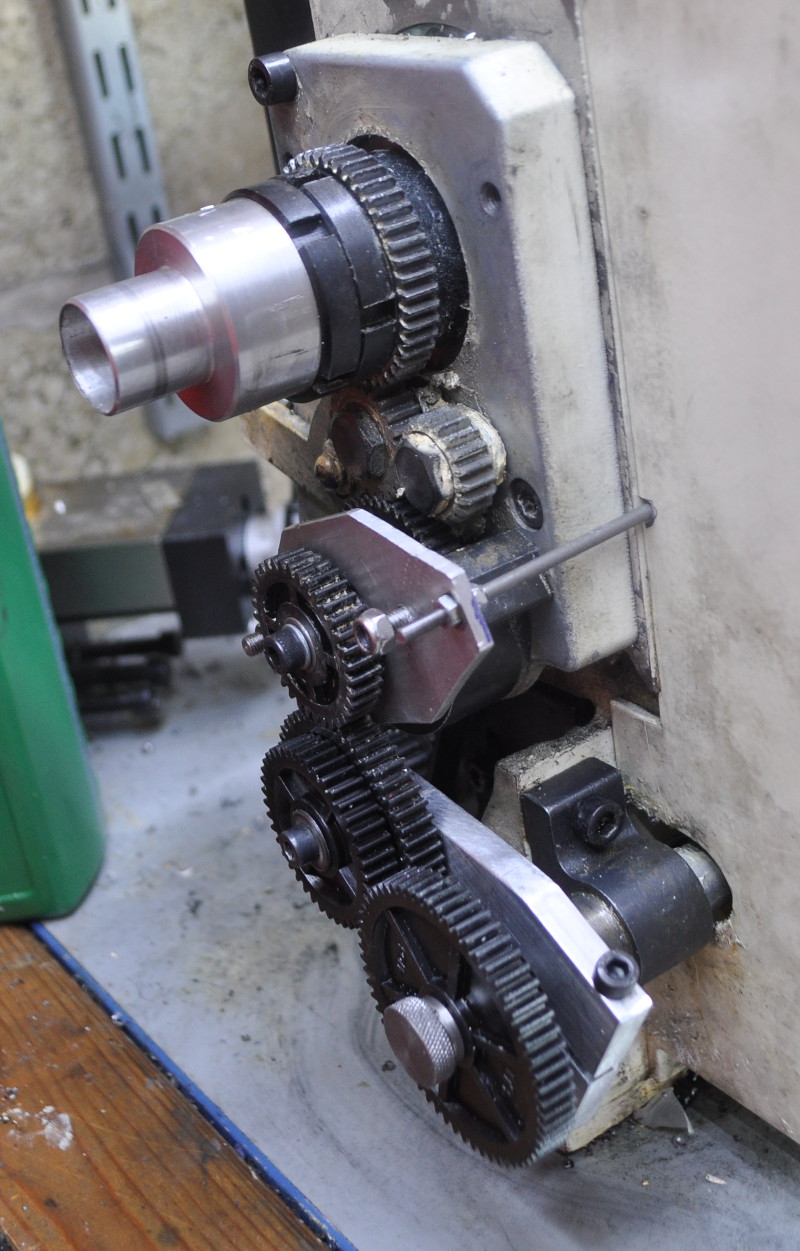

The images above show the banjo in place on the side of the mini-lathe. The left-hand image shows the banjo in place and engaged; the right-hand image shows it with the idler removed so the banjo can be seen more clearly.

|  |

The image on the left here shows the banjo from a slightly different angle. The M5 cap screw that is used to adjust the angle of the banjo can be seen in the bottom-right of the picture. My dog clutch can also be seen in this picture. The photo on the right shows a different gear-ratio where the banjo is lined up with the input and lead-screw gears.

Imperial Lead-Screws etc

Having investigated the gear ratios a bit further, I've found that for a metric mini-lathe with a 1.5 mm pitch lead-screw, 50 mm spacing is the best. For an imperial machine with a 16 TPI lead-screw, 45 mm, 50 mm, 55 mm or 60 mm could work. To get accurate-ish imperial threads with a metric lead-screw, a 60 mm spacing would work fairly well. For more information, please get in touch with the contact form.

A 3D Model of the Banjo

You'll need a relatively modern browser for this to work, but you should be able to drag it around with your mouse to look at it from different angles.

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.