Mini-Lathe Hand-Wheels

|  |

The standard hand-wheels that come with the mini-lathe aren't very pleasant to use. The cap-screw that holds them in place tends to bash against your knuckles and there is no spinner handle which makes them quite tiring to use for any length of time. Being a bar rather than a wheel, the cross-slide hand-wheel also gets knocked easily when moving the carriage.

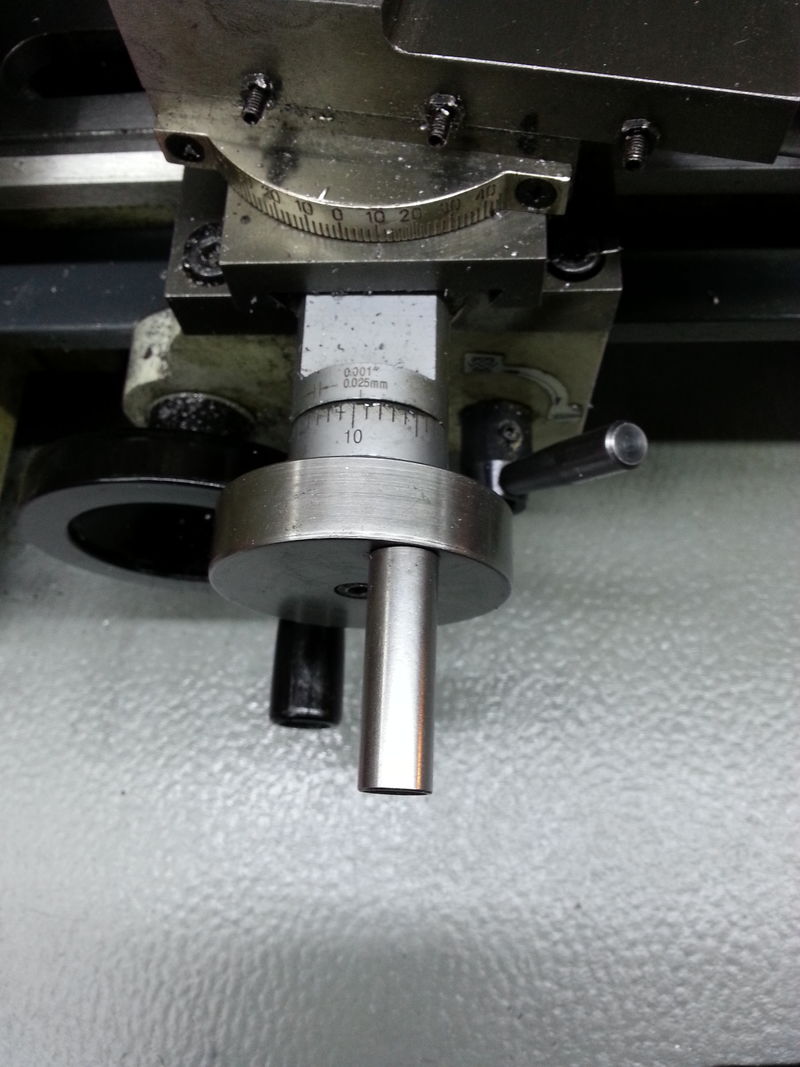

To rectify this, I made my own handles. The cross-slide hand-wheel is very simple: it is turned 59 mm diameter from a piece of 60 mm diameter rusty steel I found in a scrap bin and counterbored M6 for the cap screw. A spinner handle makes it pleasant to use.

The top-slide hand-wheel was more complicated to manufacture as the mechanism in the standard one is prone to binding if the gibs are relatively tight. This causes the dial to stay still when the top-slide moves and accuracy is lost. To improve its operation, I replaced the mounting block with one that holds a bearing. This required me to make a new graduated dial with a larger inside diameter and a groove for an o-ring that is used as a friction stop. I could have bored the dial that comes with the lathe, but I prefer (wherever possible) to keep the stock parts as-is in case I feel a need to revert a change.

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.