Cross Slide Milling

Before I bought my milling machine, I did all milling operations on the lathe. The SC2 isn't particularly capable when it comes to milling: there's too much rock in the vertical slide to ensure accuracy. The vast majority of the milling I was doing on the lathe was cross-drilling or slotting turned bars.

For cross-drilling, by far the best way I've found to do this is to use a Tailstock V-Adaptor. This makes cross-drilling effortless and accurate. This doesn't, however, help with slotting as there's no means of feeding the tailstock sideways (apart from for adjusting the alignment).

|  |

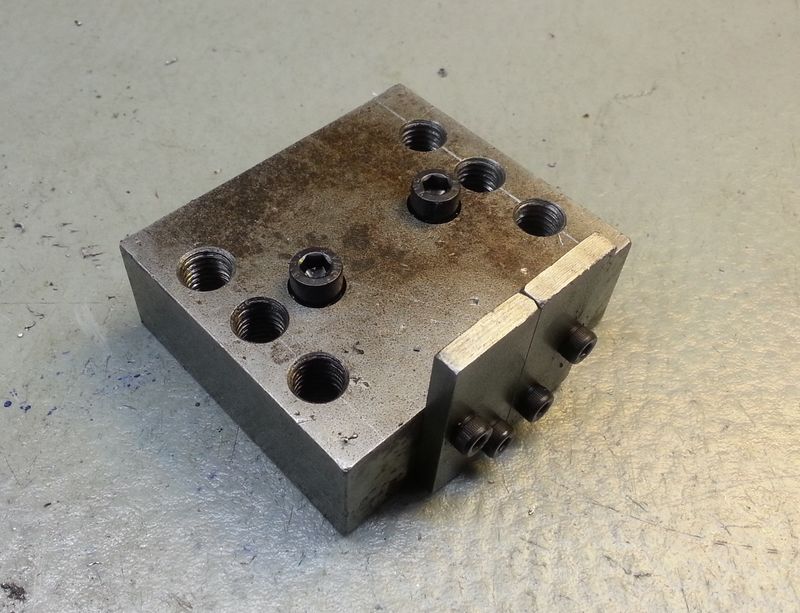

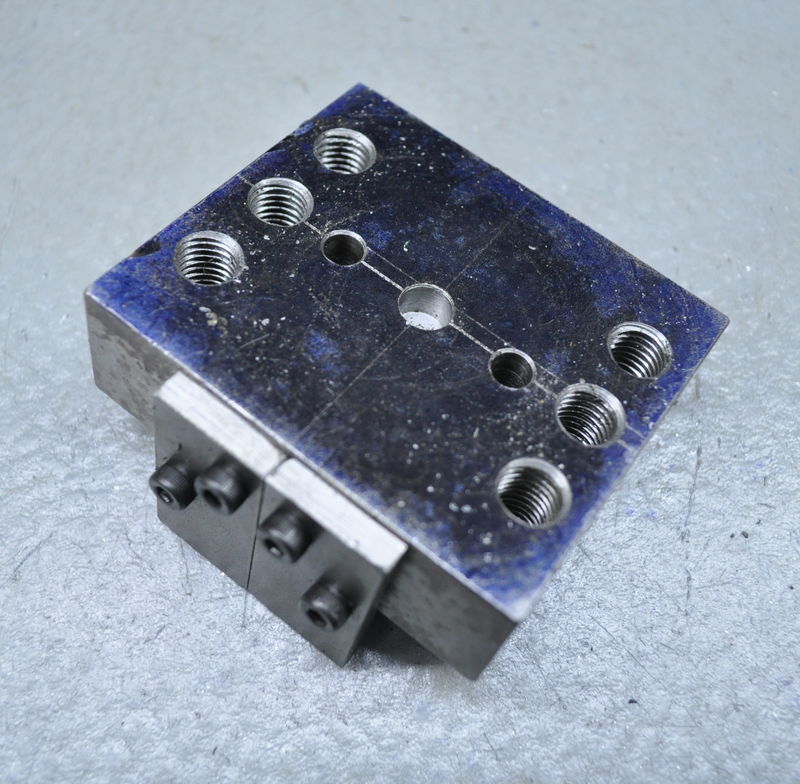

To allow me to cut keyways and similar in round bars without using the vertical slide, I built this very simple block from a bit of steel from the scrap bin. It mounts directly onto the cross slide; the dimensions were the same as the original piece of steel (it hasn't been milled at all).

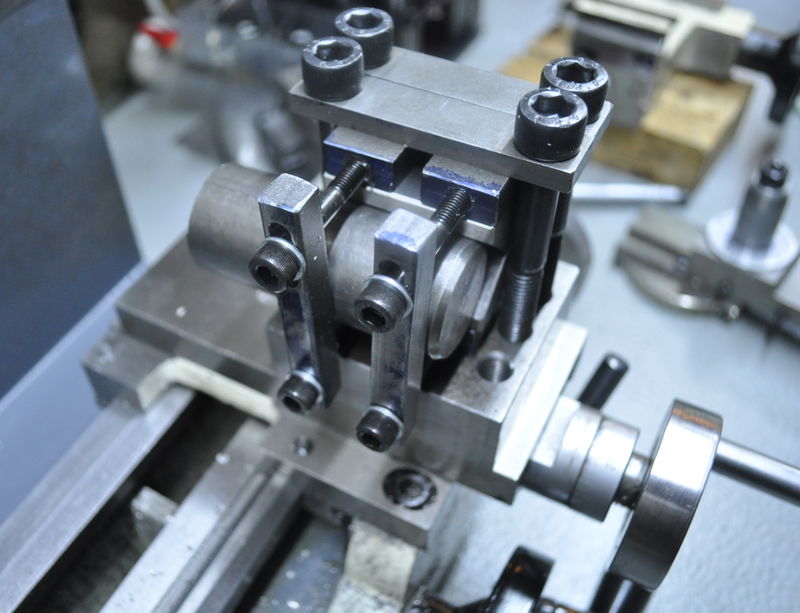

The most common use of this is to mount an ER32 collet block. To get this onto centre height and give clearance for the ER32 nut, a small piece of steel is fitted underneath the collet block. This was machined to the correct height using the four-jaw chuck. The collet block is held down with some M10 machine screws that go into tapped holes on the base block.

|  |

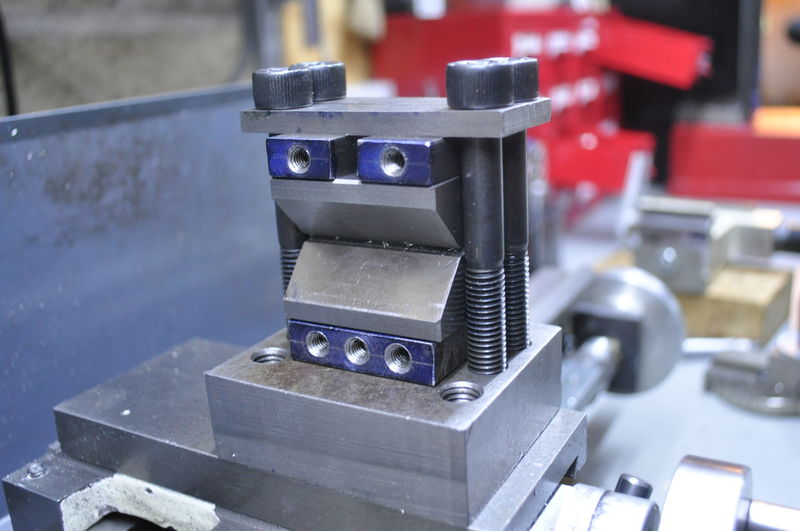

I can also mount a V-block at 90° using a similar method. Above and below the V-Block are some pieces of steel with M6 tapped holes in the side to allow the bar to be clamped into the V-Block. This is a bit of a pain to set up, so I don't use it anywhere near as much as the collet blocks (and even less often now I've bought a milling machine), but it got me out of a few awkward spots as it will hold much greater diameter parts than the ER32 collet block.

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.