Bar Clamps Build Process

5/5/2021

|  |

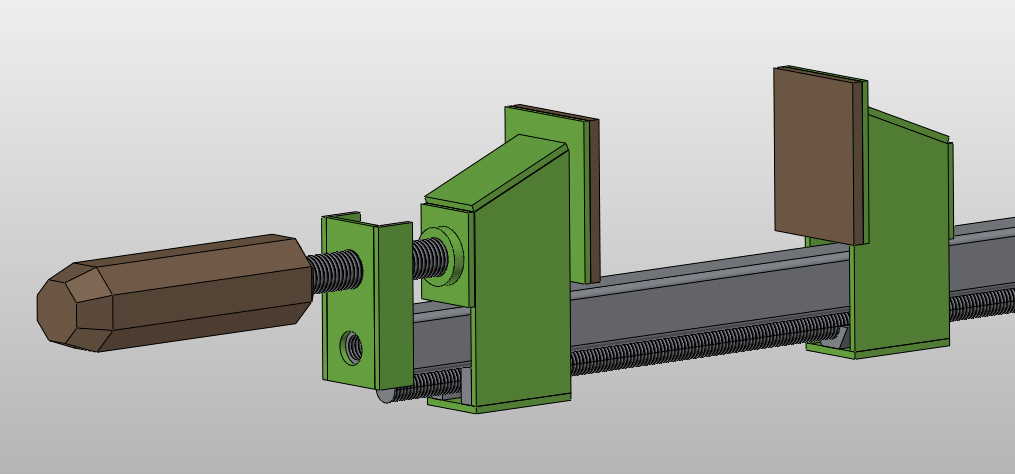

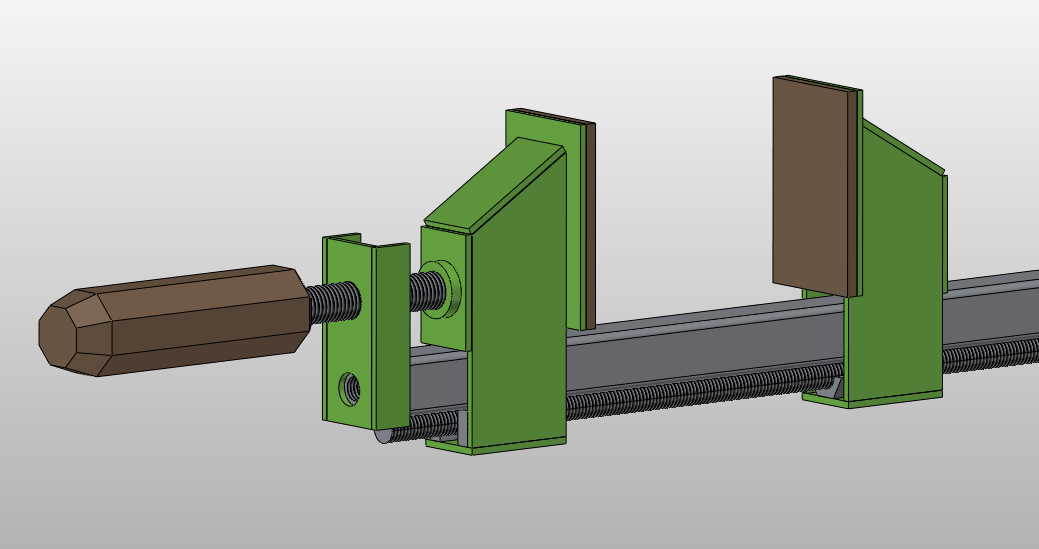

Before cutting up the all the flat bar, I need to make a decision on the height of the jaws. Taller will probably give more options for clamping, but might end up being out-of-proportion with no real benefit. Clamping at the upper extreme of the tall jaws is likely to result in a bending force being applied to the box section and the jaws may not remain parallel with one another, so tall jaws might not actually result in usable tall jaws. I've kept the screw thread fairly low on the jaws: most of the time I expect to be clamping stuff that is lying on the box section, so the bottom of the jaws is the area that is going to be doing the most work.

The ones in the first photo above look (to me) to be closer to the originals (the jaws are about 70 mm high). The second photo has 90 mm jaws; these are closer to the prototype I made.

At the moment I'm leaning towards the shorter jaws.

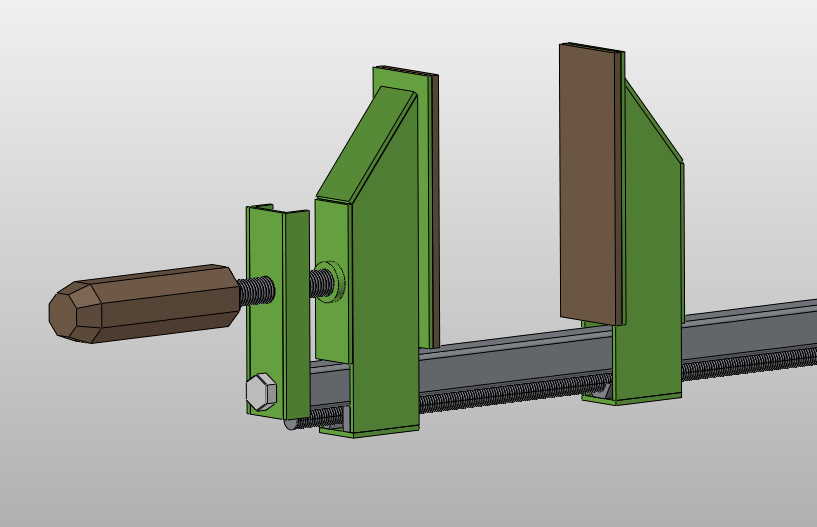

Of course, with parametric CAD, it's very easy to change things and make it look completely ridiculous:

|

Page Navigation:

| First (#1) | Previous (#5) | Next (#7) | Last (#32) |

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.