Bar Clamps Build Process

21/5/2021

|

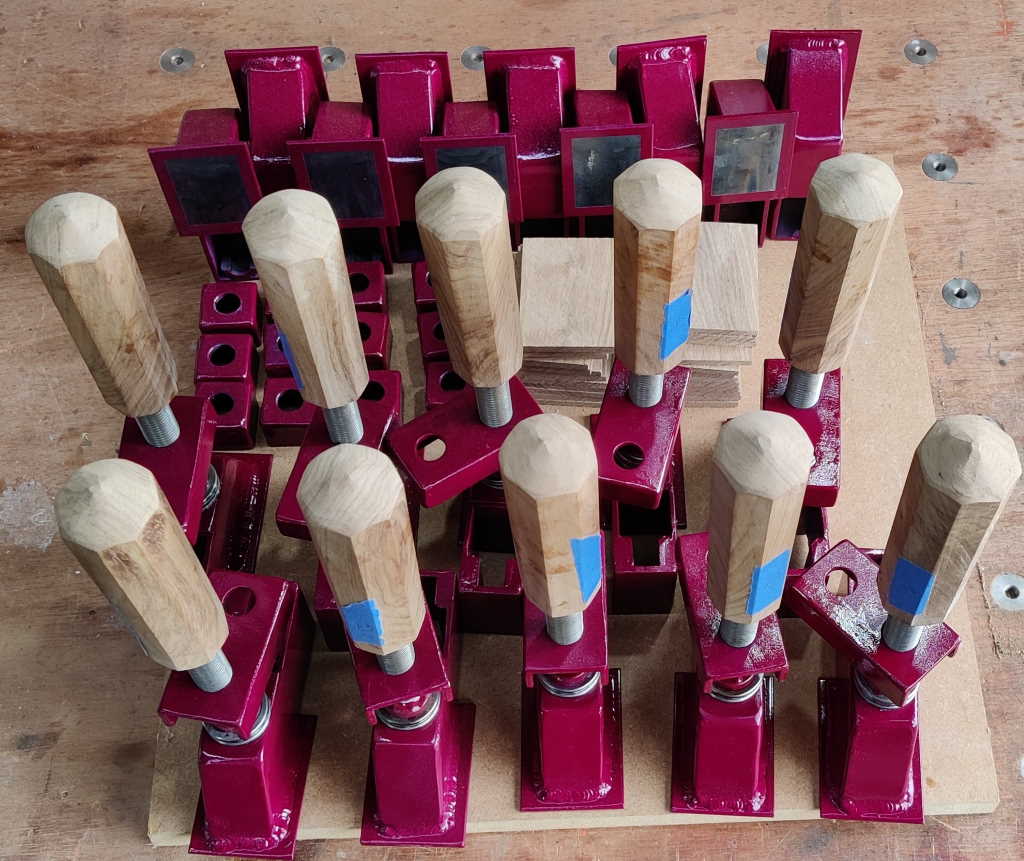

This is the photo I didn't take yesterday: the handles epoxied into place with the masking tape removed. One or two had a little bit of leftover squeezed-out epoxy that I'd missed, but it wasn't very much and was easy enough to dig out.

|

This is all the pieces fully welded, painted and glued and ready for assembly onto the bars.

After putting everything together, I found that two of the screw jaw mechanisms were very stiff. I presume this is down to one of the following:

- Too much paint inside the jaw (where it slides on the bar).

- Mis-positioning of the back face of the screw jaw so it doesn't line up with the nut on the end plate when the end plate is tightened onto the bar.

- I might have tightened the split nut too much before welding it in place.

I'll do some investigation another day; for now I'm happy that eight jaws are working fine (my target was always to make eight jaws; I made ten in case something went wrong with one or two of them).

|

Once everything was together, I took 16 of the wooden jaws and chamfered the four edges that would be on the outside (this was just done with a hand sanding pad).

|

For each jaw in turn I then put some hot melt glue on the jaw and pressed the wooden jaw pad firmly into place. Once both jaws for a given bar were on, I slid the sliding jaw up to the screw jaw and tightened the screw jaw such that it was squeezing the two pads together (and hence against their jaws).

|

After all the jaws were glued on, I loosened everything back off again ready for oiling with Danish Oil. I'm not completely convinced the hot melt glue is a good option for this (although it'll make it easy to replace the jaws if required), but if the jaws fall off I can always try a different type of glue.

|

This photo shows some of the jaw pads after having the first coat of Danish Oil.

|

This shows some of the handles after having the first coat of Danish Oil.

Page Navigation:

| First (#1) | Previous (#30) | Last (#32) |

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.