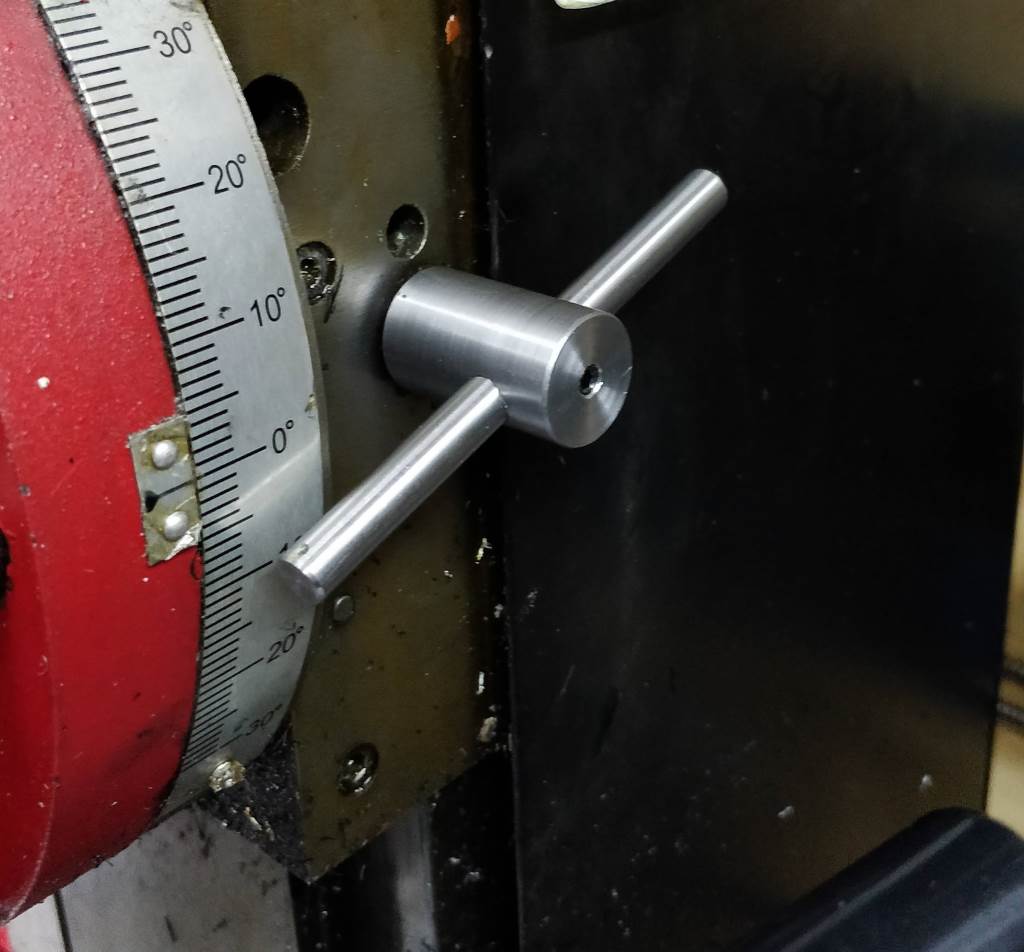

Z-Axis Locking Screw

|

This is a new locking screw I made for the Z-axis on the SX3 milling machine. It is a simple modification that I only made as a result of the original screw breaking. Having said that, I find the feel of the new screw much better and am pleased that I made the modification.

|

This photo shows the original screw. The handle part is cast aluminium and has cracked from repeated use. I rarely use the machine without the z-axis locked and, although I never tighten the screw especially firmly, repeated use has obviously caused a fatigue failure. When it broke I was hardly applying any force at all!

|

This photo shows the parts that make up the original screw. It has been designed such that the handle can be reorientated so that you can use it a bit like a ratchet spanner: only having the arm traversing a limited angle. This is required for the X- and Y-Axes due to the constraints of the other machine parts that are around the screw, but isn't strictly necessary for the Z-axis screw as it is in a more open area.

|  |

These photos show the screw before fitting. The body was turned from 20 mm diameter EN8. The end is threaded M6 for 16 mm and has a rounded end formed with a file on the lathe. There is then a 11 mm long section that is reduced to 12 mm to reduce the fragility of the long screw section (but to fit in the hole in the side of the machine). An M5 thread has been tapped in the rear of the body to retain the tommy bar (with a grub screw). The tommy bar is a piece of 100 mm long 8 mm diameter silver steel (silver steel was chosen simply because I had a piece that was the right length already and it seemed easier than cutting a new piece). A short section of the tommy bar has been filed flat to ensure that damage from the grub screw doesn't prevent it from being removed.

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.