Weighted Base Box Build Process

2/10/2021

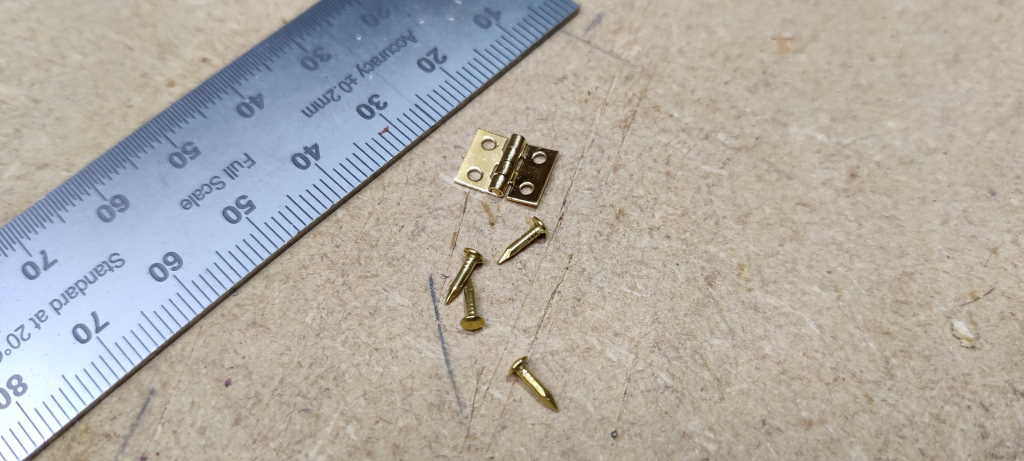

As an alternative to the cylinder hinges, I have some of these tiny (8 mm wide) butt hinges, which came with little brass nails to hold the hinges in place:

|

I measured the thickness of the hinge in its closed state: 2 mm.

|

I then bent the hinge back on itself and used it to mark (with a knife) the size of the slot. I used my marking gauge to mark a line 1 mm down from the edge as that's half the thickness I measured.

|

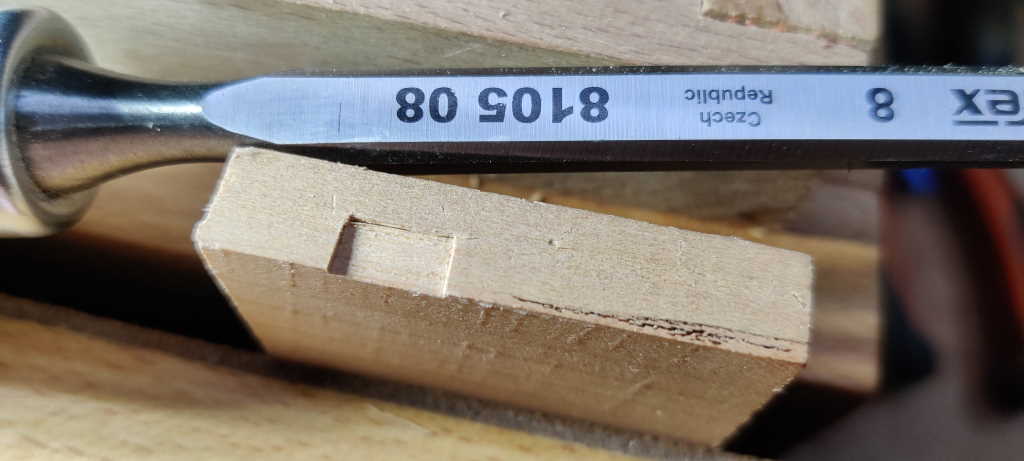

Conveniently, I've got an 8 mm chisel, so cutting out the 8 mm wide slot was very simple:

|

I could then bend the hinge back on itself again and use an awl to mark the hole locations:

|

I didn't like the idea of driving nails in so near the edge of the wood without a pilot hole so I measured the nail diameter (about 1.2 mm) and drilled a hole a bit smaller than that (0.7 mm):

|

After repeating the same process on the other piece, I could try a single hinge test fit:

|

Conclusion so far: hinges are hard and I'm not very good at fitting them!

Page Navigation:

| First (#1) | Previous (#11) | Next (#13) | Last (#18) |

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.