Weighted Base Box Build Process

3/10/2021

It's too wet to work on my Chunky Planter, so I thought I'd do a little more on the box. I started by unclamping the box so I could inspect the splines; so far they all look good.

|

I used a flush-cut saw to cut off the excess pieces:

|

All done, does anyone need any miniature V-blocks?!!!

|

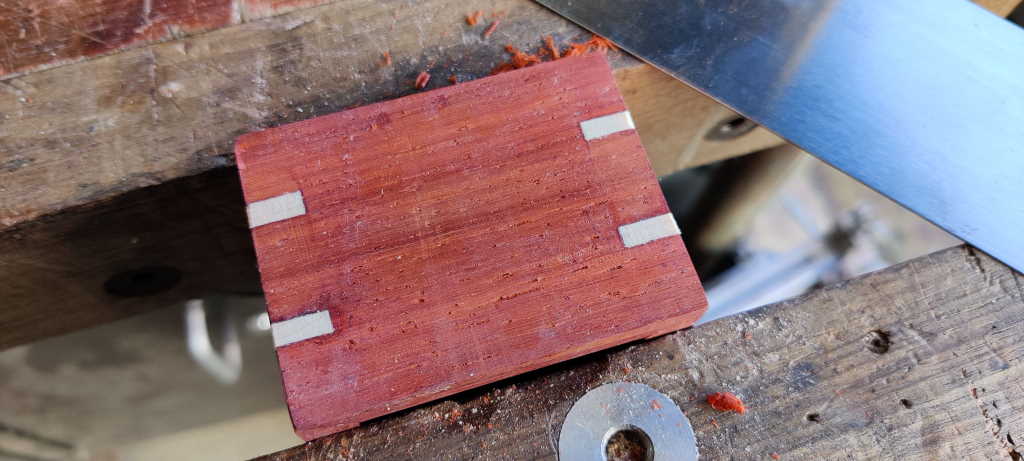

This is what one side looked like after cutting off the spline excess; you can see some glue squeeze out visible in places and some white something-or-other (maple dust maybe?):

|

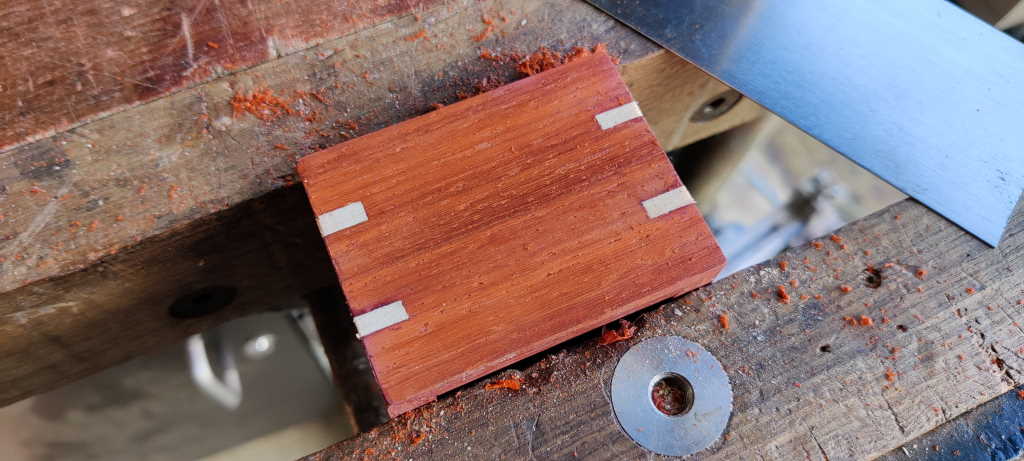

I didn't fancy sanding the sides (partly because I don't like sanding but mainly because I was worried about padauk dust colouring the maple), so I used a thin card scraper to clean up the faces of the box:

|

I then rubbed the top and bottom faces on a sheet of 240 grit sandpaper:

|

Two of the mitres (on the right of this photo) were ever so slightly gappy; it looks worse on this photo than it did in reality, but I've generally managed to get mitres spot on, so I was a bit disappointed with this. I suspect it would have been good to add some additional clamping as well as the masking tape; I probably didn't pull the masking tape tight enough:

|

I'll make those two mitres sit at the back of the box (where the hinges are), so they're not too obvious. Nevertheless, I thought I'd try cleaning them up a bit by using a very thin saw I have to cut a shallow kerf (using a combination square as a reference to make sure the cut is at 45°):

|

I then shoved some glue in the hole and covered it in the sawdust that came from sanding the top and bottom faces.

|

Once that's had plenty of time to dry I'll sand it and see what it looks like.

While the glue's drying I thought I'd have another go at a hinge test fit. I was disappointed first time round that, despite carefully measuring the thickness of the hinge, the test piece "box" didn't close properly. As a test I decided to slot the nails into the holes and measure it again:

|

It's clear that the nail heads are stopping the hinge from closing; the side view shows that the hinge ends up at an angle, which is far from ideal:

|

After pondering for a bit, I concluded the simplest solution would be to use the 240 grit sandpaper I already had on my bench to reduce the height of the brass nail heads a bit; I'd then need to polish the brass to get them looking good, which would be a bit of a chore, but there's only 8 nails, so it probably wouldn't take that long.

However, it turns out they aren't brass, just plated steel:

|

Onto plan C (whatever that may be)...

Page Navigation:

| First (#1) | Previous (#12) | Next (#14) | Last (#18) |

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.