Portable Workbench Build Process

12/3/2021

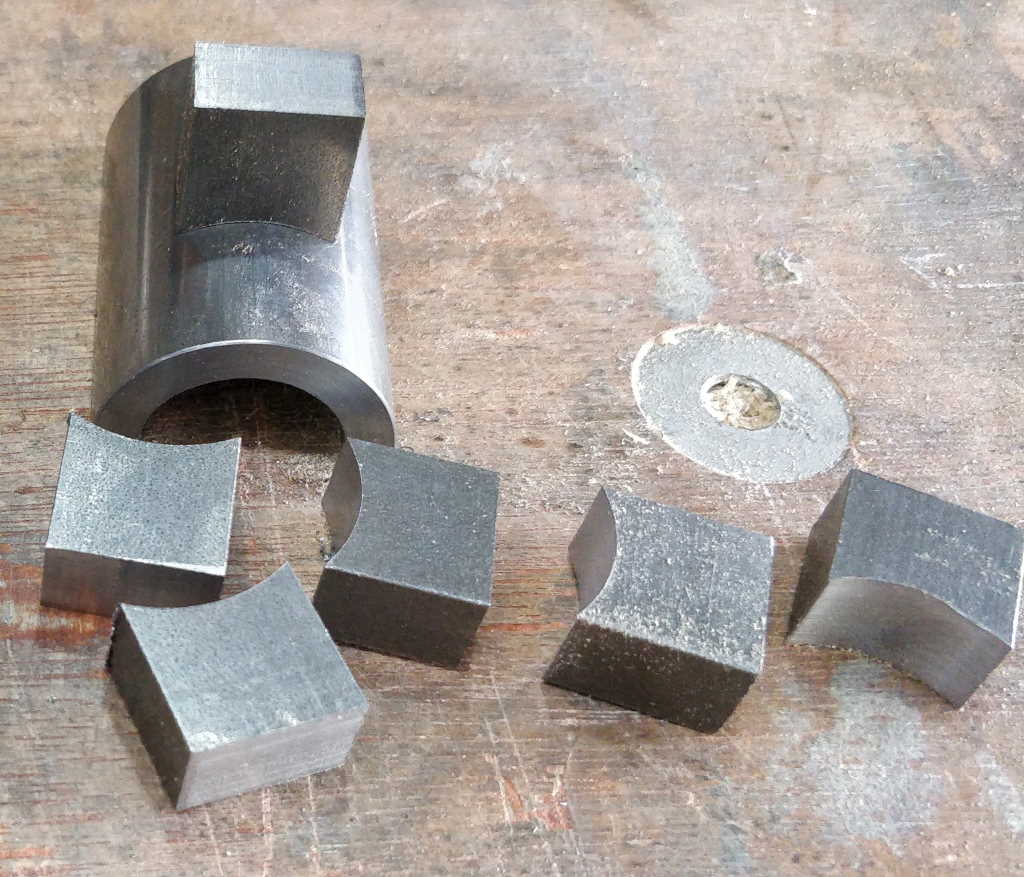

The tube hinge blocks take a bit more work than the other parts. First of all I cut the curved face. It made sense to do all six them at the same time. It didn't take me very long to do as a result of the fact that the last thing I'd used my boring head for was the prototype I made over the Christmas break. As a result the head was already set at exactly the right diameter, which made things very straightforward.

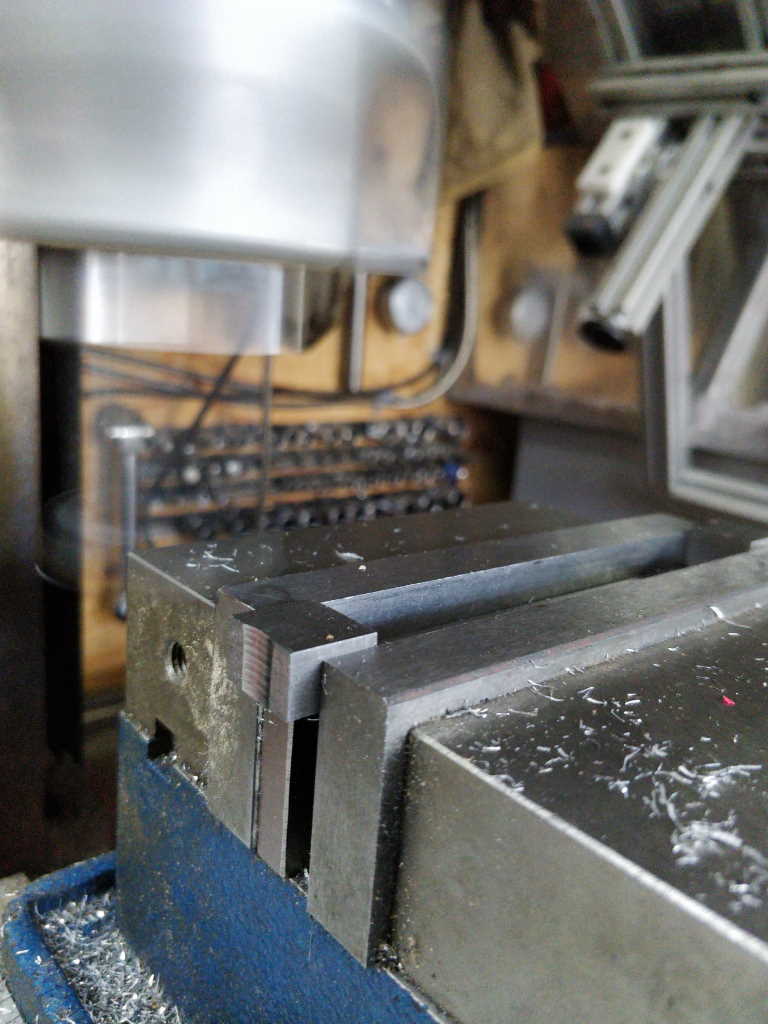

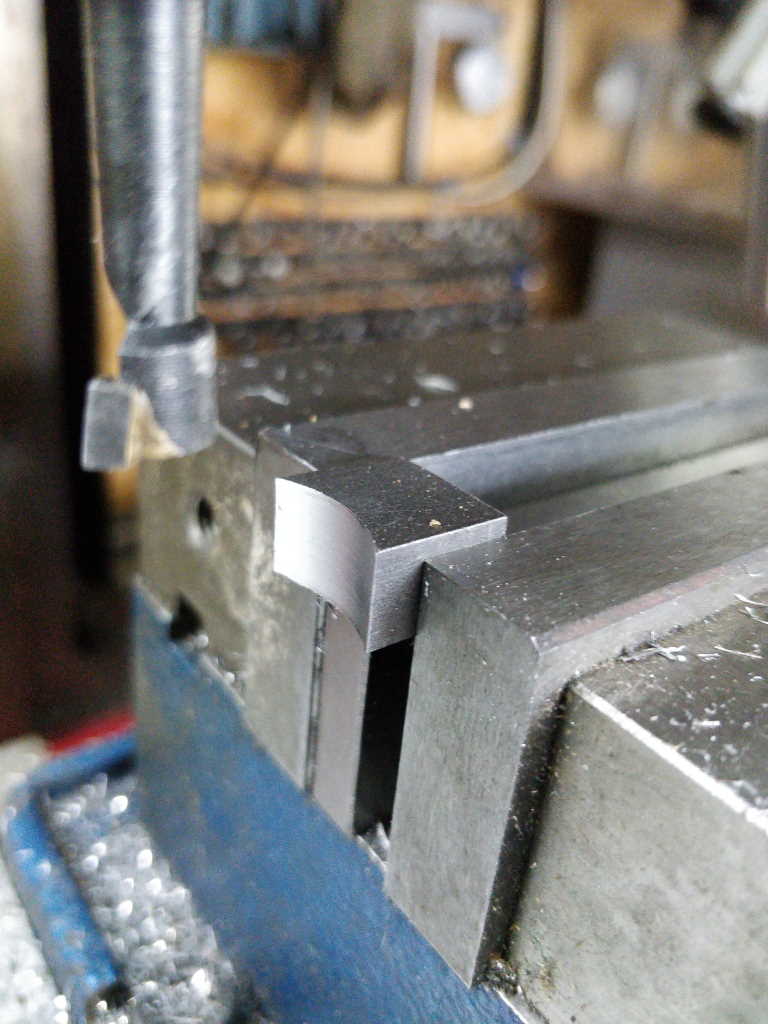

First I mounted a block on the end of the vice (with another block at the other end of the vice to stop the jaws from wandering) and used an edge finder to find the centre of the block (in Y). I moved the Y axis to the centre and locked it.

|

Then fitted the boring bar and made the cut-out in about 5 passes.

|

|

|

|

I then machined two of these blocks to length and added a chamfer on one corner. I didn't take any photos of that, so you'll just have to imagine it!

Page Navigation:

| First (#1) | Previous (#8) | Next (#10) | Last (#67) |

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.