Weighted Base Box Build Process

30/9/2021

I had an hour or so free this evening so I decided to do a little more on the box. I started by taking the masking tape off:

|

There had obviously been a bit of glue squeeze out under the tape, which was a bit of a shame, but it was easily sorted by putting some 240 grit sandpaper on the bench and rubbing the box on it:

|

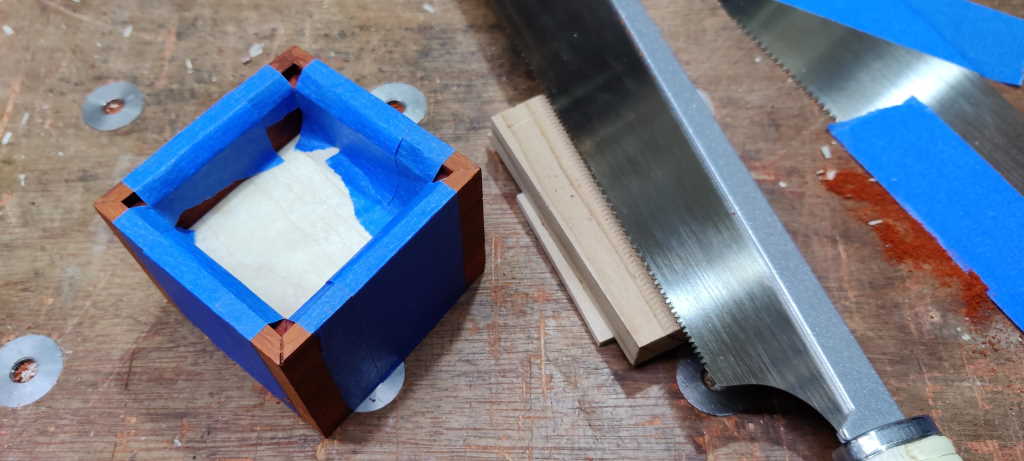

The next job was to start cutting the slots for the splines. I started by marking where I wanted the splines to get to on each side using masking tape:

|

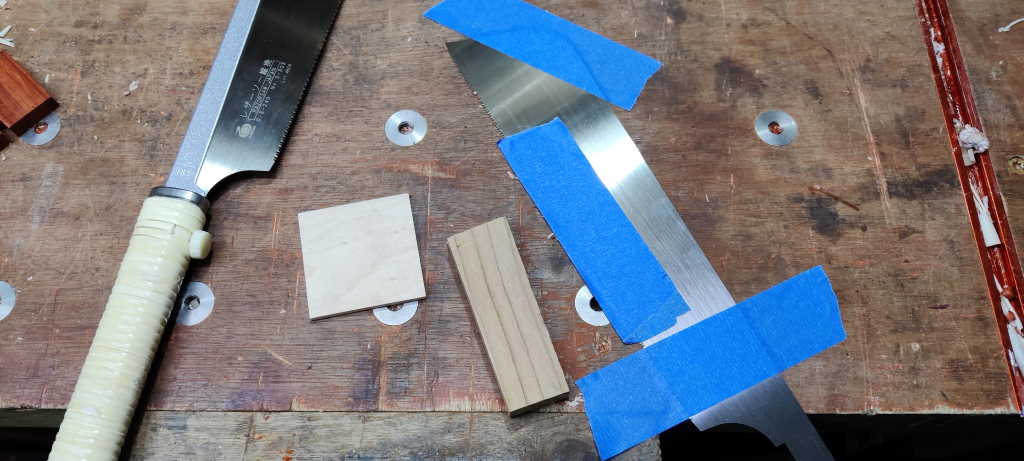

This is my spline cutting process (this is the third box I've done in a way that's basically the same as this):

|

The saw is a Dozuki dovetail saw. The small block of maple is the wood I'm going to use to cut the splines; the other block of wood is a random offcut of cedar that's 12 mm thick: this seemed about the right distance to offset the splines from the top and bottom of the box. On the right is a spare blade for the Dozuki. It's been taped down to the bench with masking tape and a couple of layers of masking tape added to account for the fact that the kerf is slightly wider than the thickness of the plate.

|

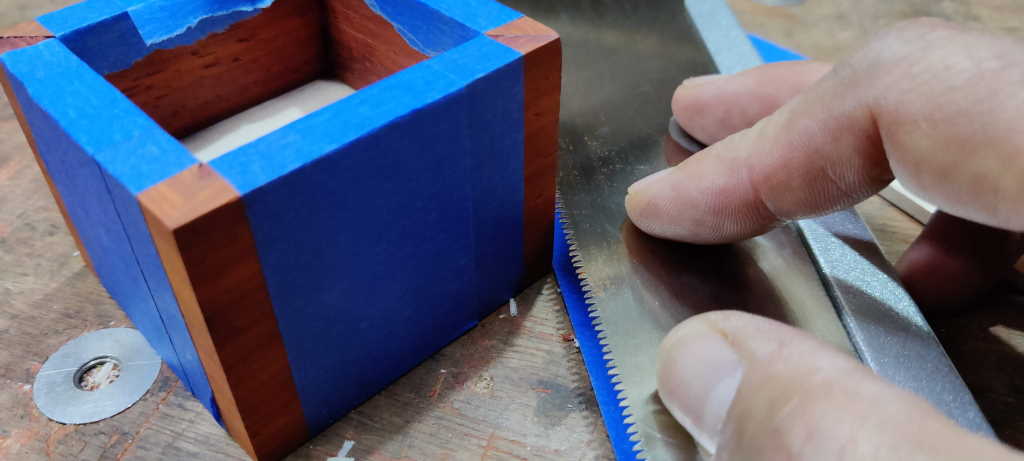

The first step in cutting the splines is to put the cedar spacer on top of the spare saw blade and then put the Dozuki on top of the cedar.

|

I can then press the blade of the Dozuki down onto the cedar and rub it back and forth to cut one side of the spline. I repeated that on each corner and with the box both ways up, so each corner had two cuts, each a little over 12 mm from the edge:

|

To cut the second side, I replace the spare blade with the maple that's going to be used to cut the spline. This effectively moves the blade up by the maple thickness minus the kerf.

|

After cutting all four corners in both box orientations, I end up with a set of slits all round the box:

|

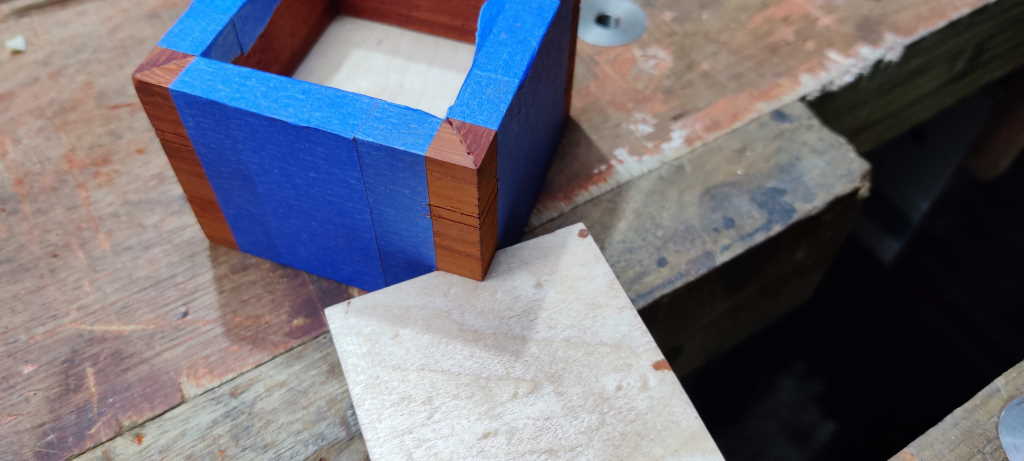

I use a square and knife to join the two saw cuts together:

|

I can then use my 3 mm chisel to open the slot out, checking with a 150 mm ruler that there are no ridges in the middle of the slot:

|

It's then ready for a test fit: if it's all gone well (which it did on the two I've cut so far), the maple piece pushes into the slot with light pressure and stays there of its own accord.

|

I've only chiselled out two of the spline slots so far; I'll hopefully get some time at the weekend to do the remaining six and get the maple glued into place.

Page Navigation:

| First (#1) | Previous (#8) | Next (#10) | Last (#18) |

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.