Weighted Base Box Build Process

25/9/2021

For a bit of a change from planing and scraping padauk, I decided to have a go at sorting out the lead for the base weight. I started by grabbing an offcut of 0.8 mm steel, scribbling over it with a magnum sharpie and marking out a simple pattern.

|

Still trying to stick to hand tools wherever possible, I used some snips to cut out the pattern:

|

Then my home-made bender was used to bend the pattern:

|

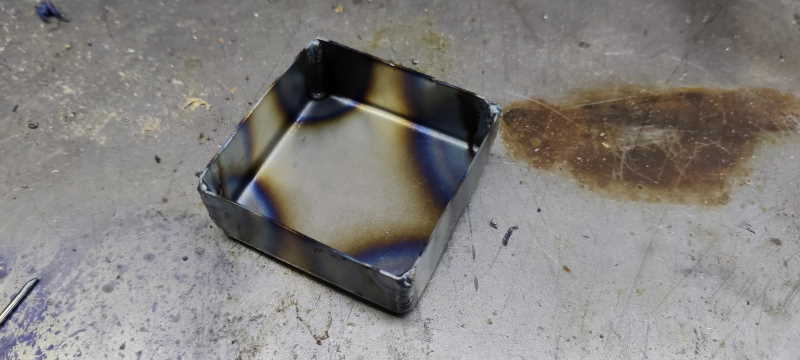

The resulting box (with inside dimensions 50 mm × 50 mm × 20 mm):

|

Next up I used both of my third hands (or should that be third & fourth hand?!) to prop the box pattern on its end.

|

I could then weld along the corners:

|

The finished steel box.

|

The plan is to use this as a mould to cast a lead block to go in the bottom of the box. I've never cast anything in my life, but lead has a nice low melting point, so it seemed a good first option. The design (such as it is) has room for a 50 mm × 50 mm × 15 mm block in the bottom, so I thought I'd make the box slightly bigger in height in case of any impurities floating to the top. It should be easy to trim it down to size after casting.

Page Navigation:

| First (#1) | Previous (#3) | Next (#5) | Last (#18) |

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.