Portable Workbench Build Process

11/3/2021

I think I've finished all the milling-machine drilling now (and I've given the milling machine a very thorough clean & oil!)

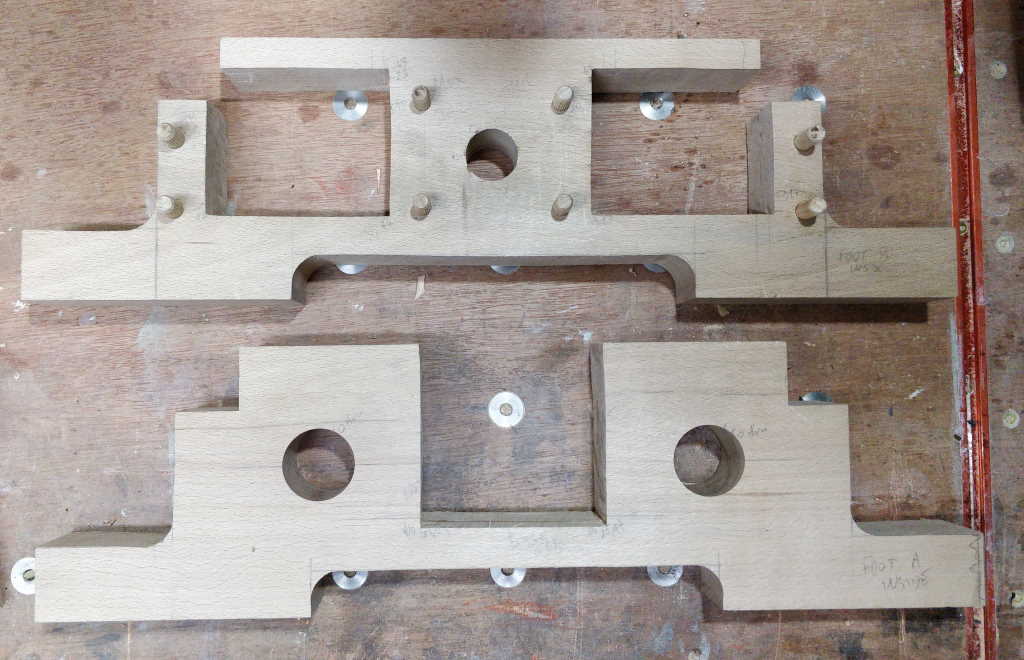

The feet now look like this (top one is the dual-screw end, bottom one is the conventional vice end - and likewise for all the other photos in this post):

|

I still need to enlarge the cut-outs for the vice mechanism but as mentioned in the previous post that can wait until later.

The inside face of the moving jaws:

|

The blind holes in the conventional vice jaw are for the slider rails. The small holes at the bottom of the pocket in the dual-screw vice jaw are for dowel pins. They'll make sure the slotted bushes go in with the slot aligned properly. The through holes are currently just 15 mm. Once the (brass) slotted bushes are in place, I'll use a bearing bit in my little router to make the beech hole match the slot in the brass. The bearing on my flush router bit will fit through that hole to get me started.

The outside face of the moving jaws:

|

The photo above makes the larger hole in the bottom jaw look really distorted, but that's just a photo artifact: it looks round and concentric to me.

The outside face of the fixed jaws:

|

For reasons I can't quite think of right now, I decided to make the screw bushes have a flange on them. It will probably look a bit better (and be easier to glue in place), but it would have been simpler to stick close to the model and just have tubes as I already have tube that would do the job perfectly! Ah well, a bit more turning is not necessarily a bad thing: it is my favourite type of metalwork after all!

The inside jaws. These now have pilot holes for the vice mechanism to mount to. I'd originally intended these to be spaced out further, but with the way the milling machine was set up, there wasn't enough Y-axis travel to get to where the bottom holes were going to be, so I had to move them closer. When I make the vice mechanisms I could add more holes further out: I could then manually spot and pilot drill them. To be honest, I doubt it'll be necessary though so I probably won't bother.

|

Next job is to make another prototype vice mechanism I think. Once that's done (and assuming it works) I can finish shaping the feet and get started making the myriad of bushes and suchlike

Page Navigation:

| First (#1) | Previous (#6) | Next (#8) | Last (#67) |

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.