Portable Workbench Build Process

3/4/2021

I started the morning thinking the only thing left to do on the bench was to fit the leather pieces to the moving jaws and then assemble everything. However, during the course of the day I had a bit of brain wave and decided to use a different method for retaining the dovetail guide. You may remember that it had been intended to be a light friction fit in the outer part of the hole, but ended up being a bit loose. Rather than try to make the hole smaller with an insert of some sort, I thought I'd just add some "bling"!

I started by drilling a 15 mm hole in the side of the foot and then drilling 11.1 mm a bit deeper. I could then screw in a threaded insert and have its head completely hidden below the surface:

|

A suitable chunk of brass was retrieved from my brass drawer and I put it in the three-jaw chuck and shaped it with my upside-down brass tool, a simple chamfer tool and a parting tool to cut some relief:

|

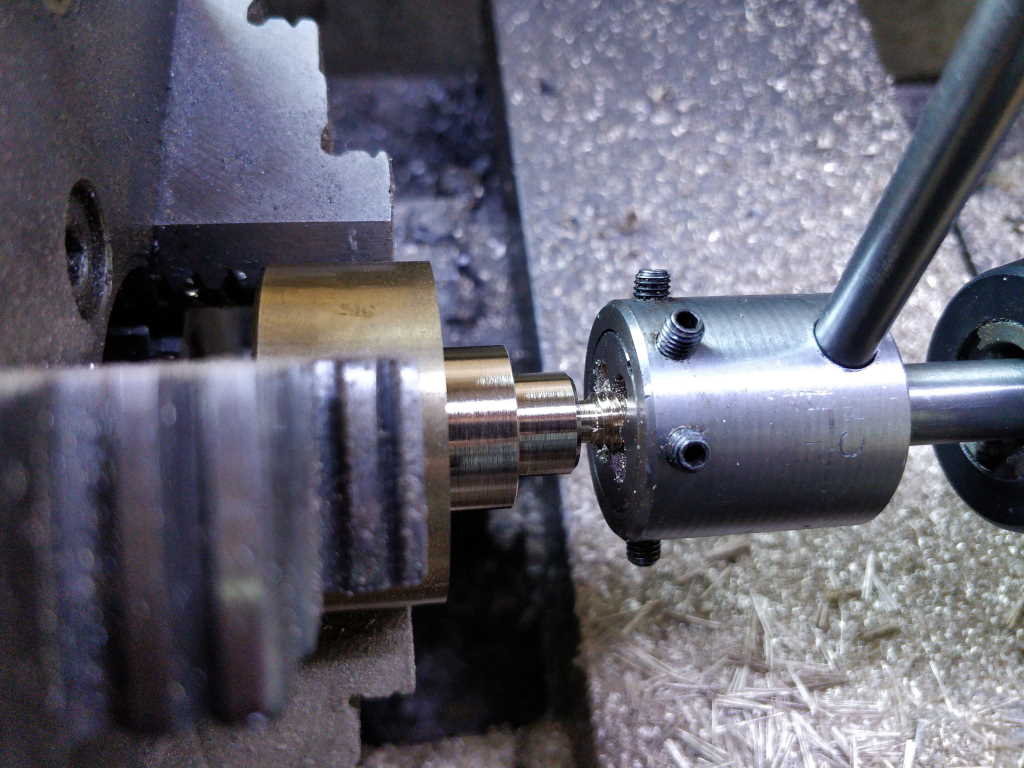

I then took the lazy option and used my home-made tail-stock die holder to cut an M8 thread on the end of the brass bar:

|

I made a quick steel insert for the rear of a collet as ER collets don't clamp very well on very short stock and having a little bit of the same diameter stock at the back of the collet makes a big difference:

|

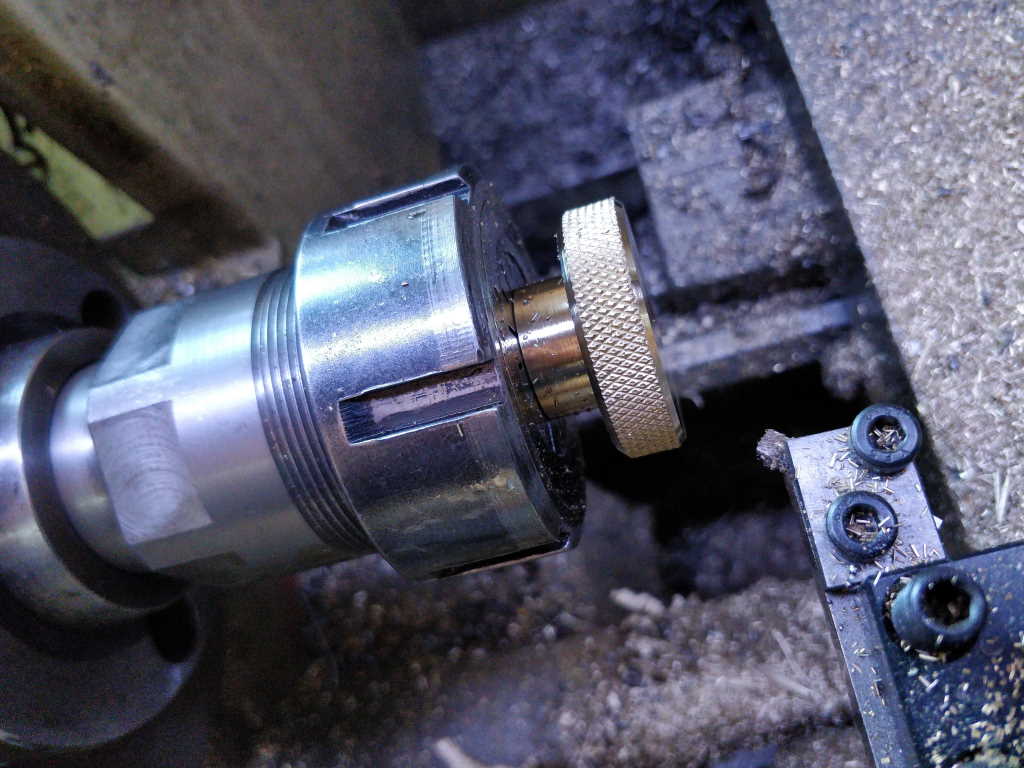

I then fitted the collet chuck, clamped the brass piece (the other way round to how it was mounted in the three-jaw chuck) in the collet chuck and turned it down to 39.57 mm (which, according to my knurl calculator is the next size down from 40 mm for a good pattern with my knurls). I know many people say that you don't have to get the diameter right before knurling, but I've always had good results when I have set the diameter right and given it only takes a few seconds to do a finish pass before knurling, I always do this.

The oil pump was turned on and I got knurling:

|

I then put the upside-down tool back in the tool-post and turned away a lot of the excess, before chamfering both sides:

|

Page Navigation:

| First (#1) | Previous (#63) | Next (#65) | Last (#67) |

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.