Portable Workbench Build Process

8/3/2021

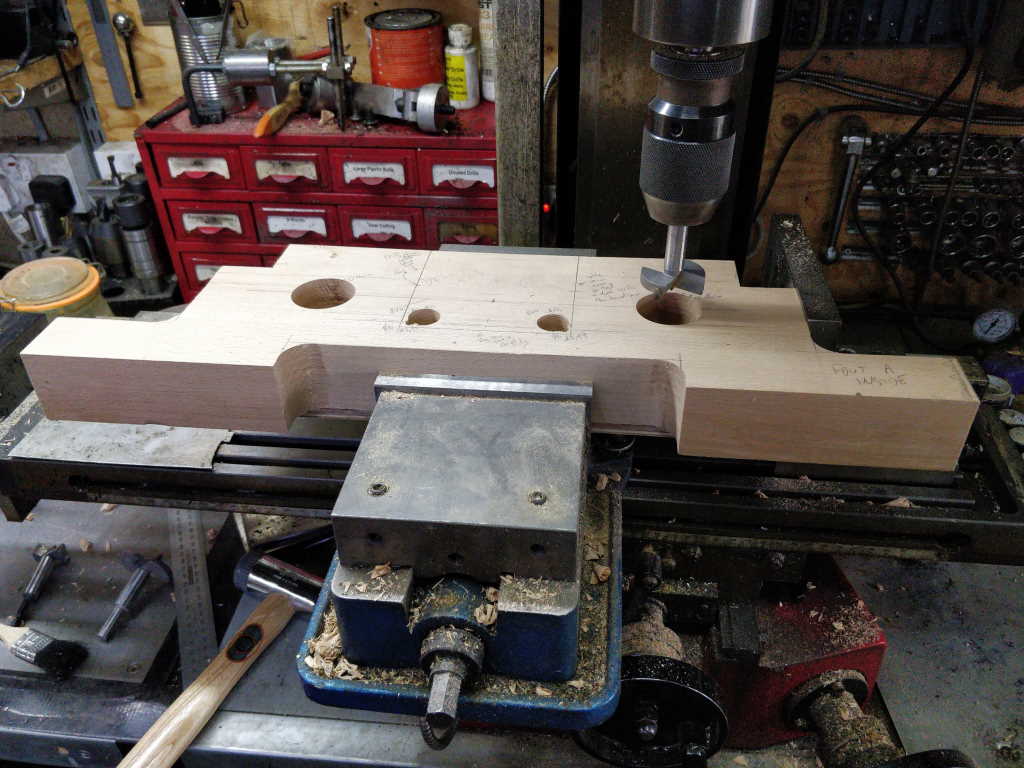

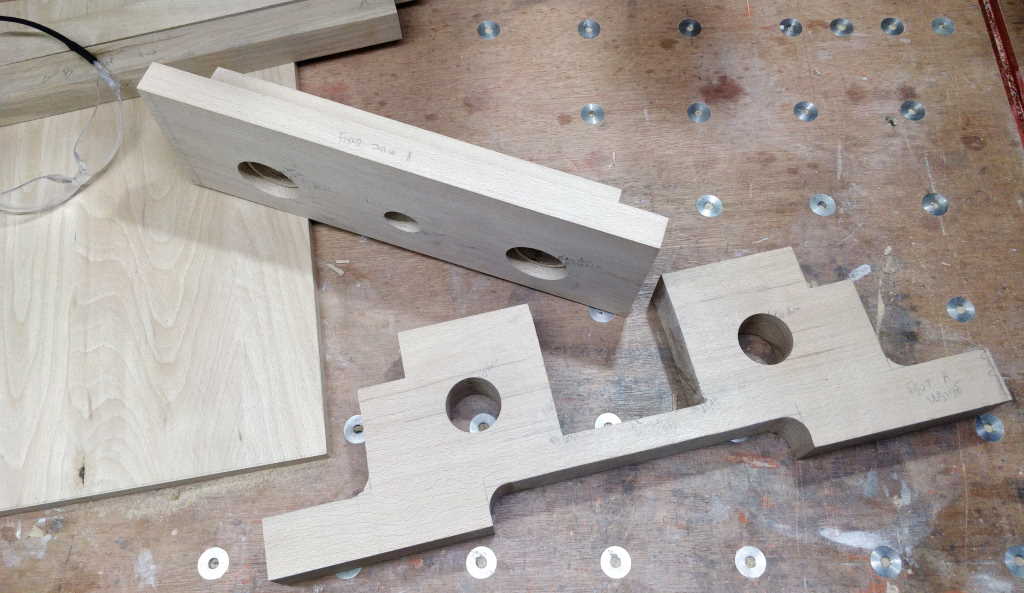

I made a little bit more progress tonight. I started by drilling out the holes in the foot and fixed jaw for the conventional vice end of the workbench. The fixed jaw was simple: all drilled from one side; three holes drilled through with two opened to a bigger diameter to depth 10 mm. The foot involved a couple of through holes and some other holes for jigsaw access:

|

After that, I clamped the foot in the bench vice and sawed down to the holes:

|

I was a bit more confident on the second cut and went closer to the knife line:

|

I then used the jigsaw to separate the two pieces:

|

Then (after sharpening the chisels I used yesterday), I tidied it up:

|

Am I the only one who finds end-grain chisel shavings like this extremely satisfying?

|

Then a bit of final tidying up of the slot with a saw rasp again (although no-one will ever see these faces) and I called it a day:

|

Page Navigation:

| First (#1) | Previous (#4) | Next (#6) | Last (#67) |

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.