Portable Workbench Build Process

12/3/2021

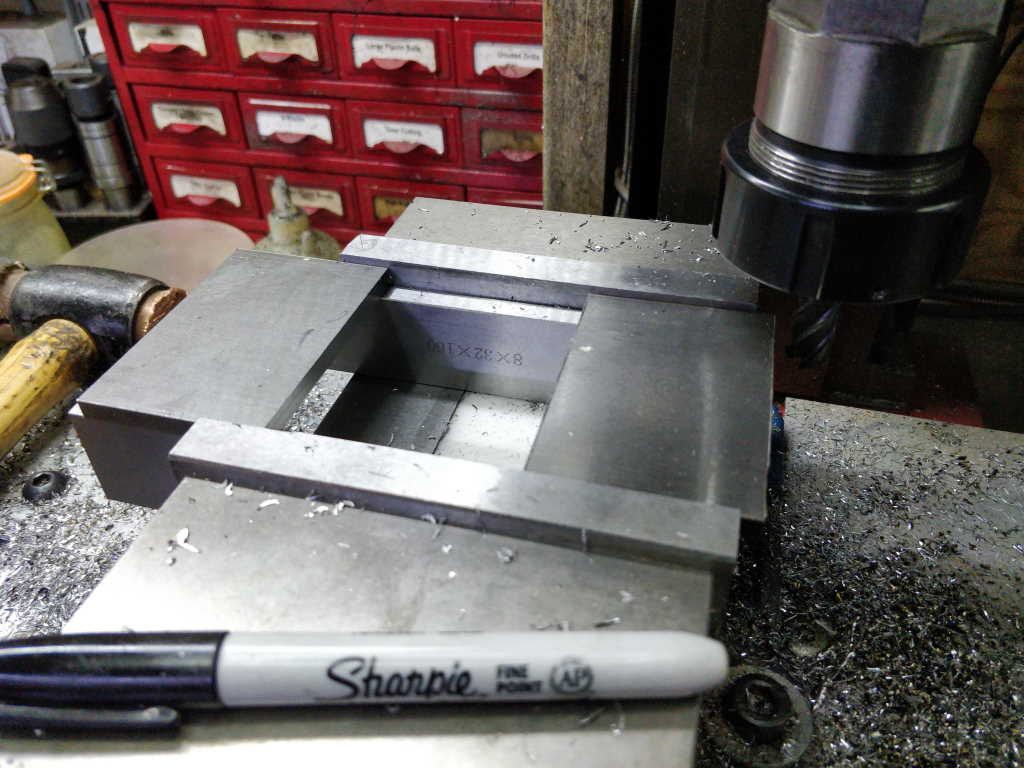

Last job for the day was sizing the bits that will make up the vice mechanism body. First of all I used the side of an end mill to square up one end of each part (none of these components need to be especially accurate and this is a quick and easy way to do it):

|

Then I got a carbide insert face mill (which is wide enough to cut all the bits in one go) and cut the opposite end to length - this ensures the two ends are parallel with one another and that's all that really matters here:

|

Action shot (one of the less significant advantages of my home-made X-axis power feed!):

|

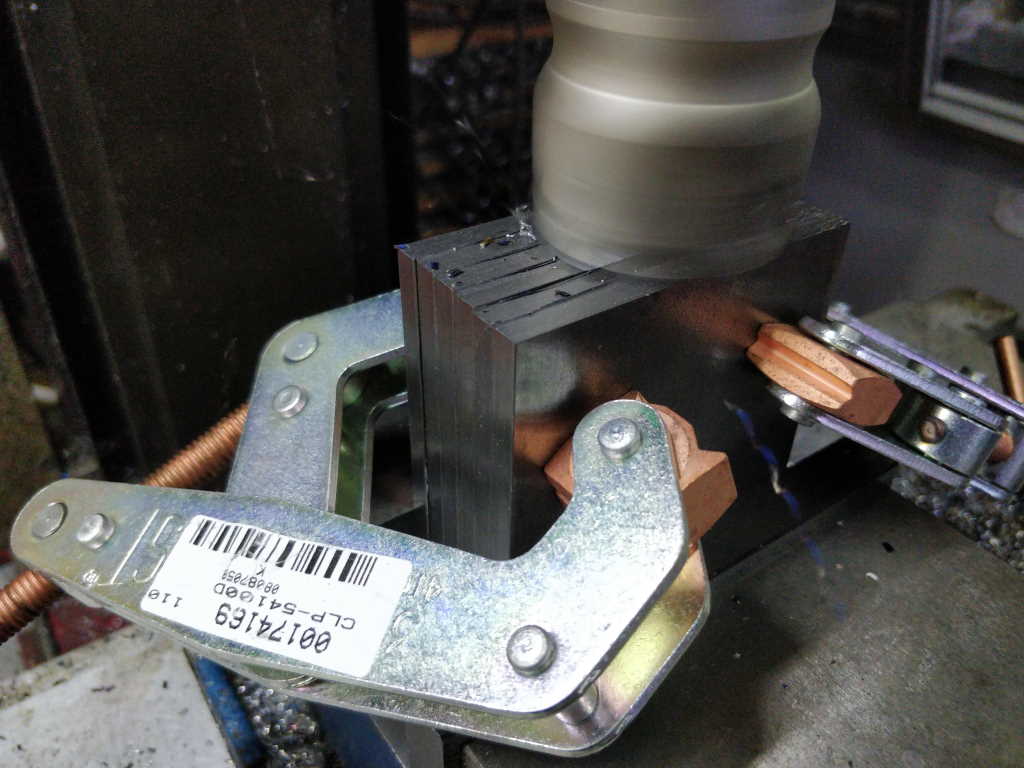

For the (longer) front and back pieces of the body, I added some extra clamps while face milling to make sure they didn't wobble around:

|

That's it for today. Tomorrow I'll drill the holes in the box front and back pieces for one vice mechanism (possibly using a bit of scrap instead of the real bits) and weld the lock mechanism together. If that works it's full steam ahead; if it doesn't work it's back to the drawing board!

Page Navigation:

| First (#1) | Previous (#10) | Next (#12) | Last (#67) |

This website is free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.